According to the latest report from Environmental Audit Committee in UK, the global consumption of takeaway drinks causes a major threat to environmental problems. In spite of the rising coffee consumption globally, the production of disposable coffee cups is growing rapidly. Saxon Write, an Australian coffee businessmen senses the crisis and would like to make a change. As Australians throw away 2.7 million takeaway coffee cups a day, 1 billion every year. He decided to try out a closed loop “Crop to Cup system” by launching Huskee Cup in the market to solve waste problem in coffee industry, not only on consumer but also farm level.

What’s wrong with Coffee Husks?

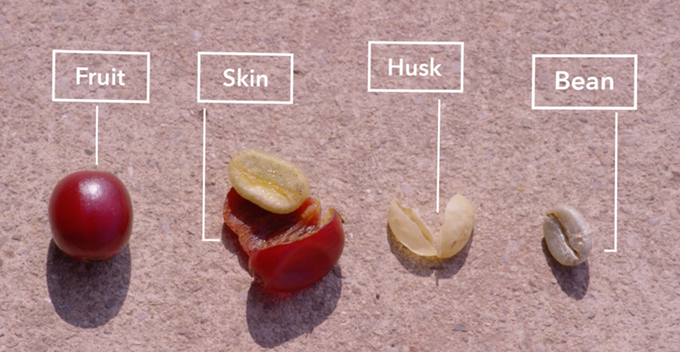

In fact, annually 1.35 million tonnes of husks are wasted globally, and the average coffee drinker contributes about 3 kilograms of husk waste every year. Therefore, Saxon Wright and his team designed a reusable ceramic alternative made from discarded coffee husk, i.e. the layer of cells that coat a coffee bean. They collected Coffee Husks from Yunan, their source of Coffee farms in China. Moreover, they utilise their design thinking to make sure Huskee cup can be “Less Waste & Plastic. Recyclable. Durable. Thermolabile” . “Otherwise, they are still just another plastic cup”. Saxon Wright said.

A Win-Win solution: a closed loop Crop to Cup system to solve waste problem at cafe and farms level

“We wanted to create a closed-loop system, so we thought if we could use waste from farming to create a cup we could solve problems both at the cafe and farm level,” he said. As a nutrient-void waste material, coffee husk is produced at the milling stage of coffee production. It is traditionally discarded by farmers and left in mounds to go mouldy. HuskeeSwap is a world first takeaway cup replacement system that’s convenient and designed with your cafe in mind.

“When the path reveals itself, follow it”

“The challenge is how to use as much as husk as possible, whilst perserving all the characteristics of the design intent and usefuly quality.” Since July 2017, they launched a crowdfunding campaign on Kickstarter and unexpectedly raised $114k which accelerated the production of Huskee Cup and Lids in full speed. Currently the Huskee Cup is undergoing the final lab test and approval is in progress to make sure the product safety. First batch of order is expected be ready for delivery in summer 2018.

Source of Information: Huskee & Sydney Morning Herald